Performance

Testing and product validation is a critical aspect of supporting any product claiming biodegradability. Reverte™ has been demonstrated to provide reliable, safe and reproducible biodegradation results in a range of polyolefin films tested to internationally recognised standards.

Performance - Biodegradation Results

Reverte™ has been demonstrated to provide reliable, safe and reproducible biodegradation results in a range of polyolefin films tested to internationally recognised standards.

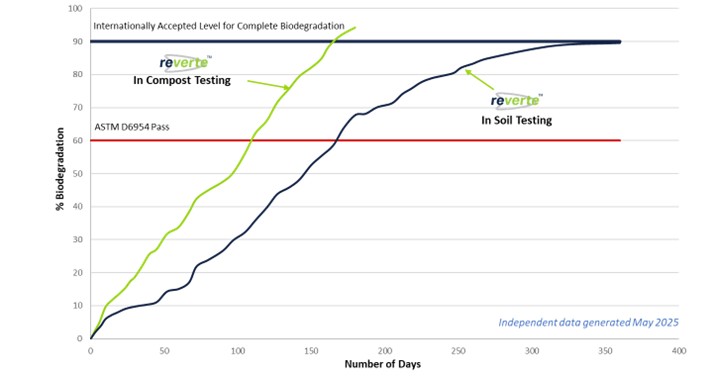

Reverte™ treated polyethylene film (containing 1wt% of Reverte™ BD92771) has been tested under ASTM D6954-24 conditions by an independent laboratory. The Tier-2 testing was conducted both to ASTM D5338 (composting) and ASTM D5988 (soil biodegradation) over a 180-day and 360-day period respectively, the results confirm biodegradation of both tests ≥ 90%, meeting the internationally accepted level for complete biodegradation.

This is clear demonstration of the use of Reverte™ biodegradable additives as an effective method to render standard polyolefin films totally biodegradable, passing the 90% biodegradation mark which internationally is considered ‘totally biodegradable’ in both composting and the more challenging soil environment.

The level of proven biodegradation as a result of Reverte™ transforming the polyolefin to low molecular weight biodegradable materials demonstrates that no microplastics are formed.

- Reverte™ has been independently tested and proven to safely biodegrade polyethylene, polypropylene and polyester films in accordance with ASTM D6954-24, producing CO2, H2O and biomass, it does not produce microplastics.

- Reverte™ treated films have been shown to have no toxic effects when tested in accordance with OECD 207 & 208.

- Reverte™is approved for use in food contact applications according to EU and FDA legislation.

- Reverte™ does not contain heavy metals such as those prescribed by EN13432 and RoHS3 such as but not limited to cadmium, chromium (VI) lead or mercury.

- Reverte™ containing films are suitable for both mechanical and chemical recycling.

Standards

Reverte™ also holds a number of important quality marks, recognising not only the compliance of Reverte™ with local standards but also the quality and manufacturing procedures, controls and processes in place to deliver the highest possible quality and support of any biodegradable additive manufacturer.

Please click Here to view the current certificates.

In addition, Wells PM has collated extensive independent third-party testing results and thousands of internal Tier One tests for our customers generated in our onsite laboratories operating in accordance with ISO17025.

Talk to us about how Reverte™ can enhance your products

Please complete the contact form below providing as much detail about how Wells can help you

Wells Performance Materials

Largest independent specialist additive masterbatch and compound manufacturer in the UK