Reverte™

Part of Wells Performance materials Group

Making Ordinary Plastics Biodegradable

Reverte™ is a family of products which, when added to a range of commonly used polymers makes them ultimately safely biodegradable*

What is Reverte™

Reverte™ is globally recognised as a family of masterbatches which have been developed to make a wide range of polyolefins such as biodegradable packaging.

Reverte™ is a complex formulation of additives that when added to a polymer can after its useful life cause the long polymer chains to be transformed via an oxidative process into non-plastic materials, these materials have much lower molecular weights which are in turn biodegradable.

Reverte™ only has to be added at small amount in order to be effective in a wide range of applications from carrier bags, packaging, flexible films for food, through to agricultural mulching films.

What we do

Distributors

Part of Wells Plastics

Mode of Action

Reverte™ is introduced, for example in a check out bag, at the manufacturing stage. Just like a blue colour might be added via a colour masterbatch, Reverte™ is in masterbatch form to ensure the complex formulation is able to be easily handled and accurately dosed by the polymer processor.

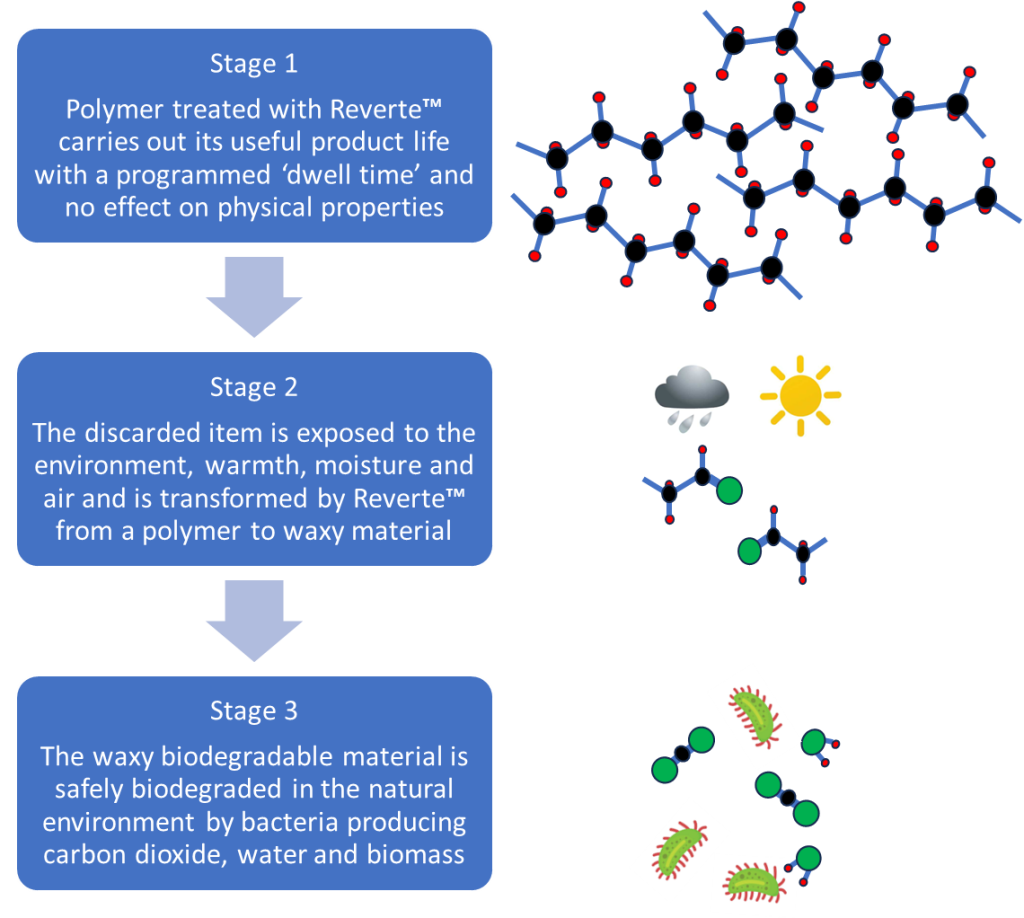

Like all polymers which can become biodegradable, whether that be a polyolefin or a biopolymer a process needs to occur which changes the polymer from large bulky hydrophobic molecules which cannot be biodegraded by microorganisms into much smaller (non-plastic) molecules which are hydrophilic and can be used by flora a fauna as a source of food.

The Process

- Oxidation of the polymer due to heat/light in the open environment.

- Mw reduction; structural/chemical changes; loss of mechanical integrity, which under the action of wind/rain, causes a transformation into waxy, non-plastic materials.

- The molecular weight of this new material is greatly reduced to between 4,000 and 10,000 Daltons and is now biodegradable within the environment.

- This waxy biodegradable material can be used as a food source by microbes safely and harmlessly biodegrading the material, converting the carbon to CO2, water and biomass (growth).

Reverte™ has been independently tested to ASTM D6954-24 confirming its performance as a biodegradable additive to polyethylene, polypropylene and PET films and that it is both safe and does not produce microplastics.

Why Reverte™

Reverte™ has been in continuous development and supply into global marketplace for over 20 years becoming the Reverte™ range in 2005. Wholly developed and manufactured by Wells, supported by a state-of-the-art Polymer Innovation Centre and an extensive manufacturing capability Wells is able to provide a total service.

Reverte™ is distributed around the world through a network of specially selected distributors to ensure local supply and support.

The Wells team are recognised internationally as experts in the field holding Technical Lead roles in bodies such as ASTM to develop and improve biodegradable standards and founding organisations such as the Society of Biodegradable Polymers.

Reverte™ is considered technically superior to other biodegradable additive technologies in the marketplace, offering a greater degree of control and predictability.

Benefits of Reverte™

- Reduces impact of litter in the environment.

- Does not produce microplastics.

- Adds value to products and brands.

- Small addition rate, generally 1%.

- No modification or investment in machinery required for manufacturers.

- Cost effective method of enhancing the environmental credentials of plastics.

- Allows all the performance aspects of your polymer blend to be maintained.

- Supported by Wells Innovation Centre and Manufacturing facility.

- Wells is globally recognised as the technical leader in the field.

Find out how our Biodegradable Solutions can help you

If you think that your product would benefit from our Biodegradable technology, please get in touch

Wells Performance Materials

Largest independent specialist additive masterbatch and compound manufacturer in the UK